Ceramics Materials detail

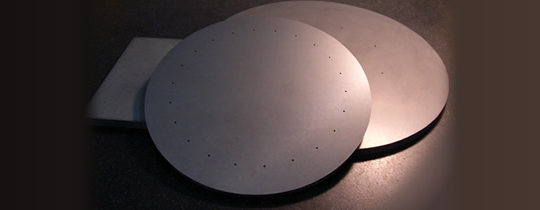

MACOR®

Machining tolerances are surprisingly tight.

MACOR® is an ideal material in ultra-high-vacuum environments, its zero porosity contributes to no outgassing and lower helium permeability.

Feature

- Ultra-precision machining

- Surface finishes

Cutting<4μm, Grinding<2μm and Polishing<0.01μm

Thin sheet thickness: Minimum 30 μm - Rate of gas permeation and outgassing are lower than Pyrex glass

- Excellent resistance to radiation

Dielectric Breakdown voltage 40kV/mm

Volume Resistivity 1016Ωcm at RT - Low thermal conductivity

Applications

Insulating materials in vacuum, Medical equipment parts,Insulating materials for radiation therapy machine, Electric gun parts, Ultra low temperature applications

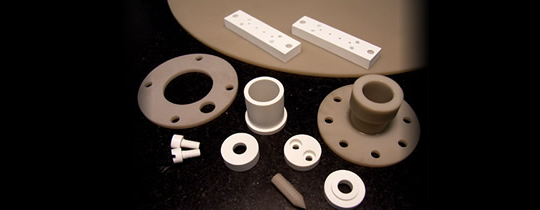

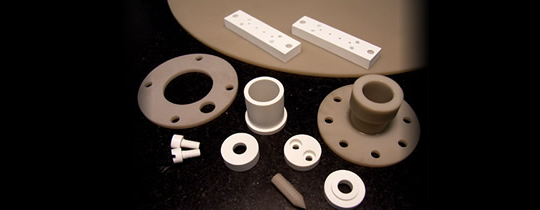

SHAPAL®Hi Msoft

SHAPAL®Hi Msoft provides a flexural strength similar to Alumina and high thermal conductivity.

Maintains its flexural strength up to 1,000℃.

Feature

- High thermal conductivity (92W/m・K)

- Excellent rigidity

- Outstanding electric characteristics

Dielectric breakdown voltage 50~60KV/mm

Volume resistivity 1014Ωcm at RT - Low coefficient of thermal expansion

- Excellent heat resistance

Applications

Thermal dissipation, Dielectric strength in vacuum chamber, Substrate material, Bush, Nozzle for high temperature

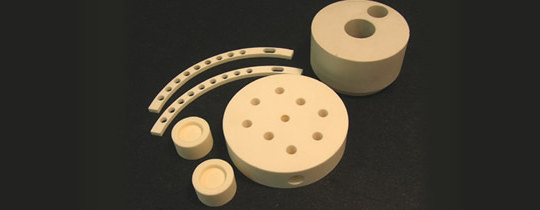

Boron-nitride

Boron-nitride and Aluminum-nitride have unique characteristics such as high thermal conductivity and low thermal expansion

Feature

- Excellent thermal shock resistance (T=1500℃)

- Low wettability and high-corrosion resistant to molten metals

- High thermal conductivity

- Maintain high performance at high temperature because of its chemical durability

Applications

High temperature dielectric strength, Fixtures and crucible for molten metals, Shelf board for heat treatment

Aluminum-nitride

Boron-nitride and Aluminum-nitride have unique characteristics such as high thermal conductivity and low thermal expansion

Feature

- High thermal conductivity

- Coefficient of thermal conductivity similar to Silicon

- Withstand fluorine plasma

Applications

Semiconductor manufacturing equipment parts, Heat sink

Alumina

Versatile material representing engineering ceramics because of its excellent mechanical and electrical properties.

Large size is available at inexpensive price.

Feature

- High strength and wear resistance

- Excellent chemical durability

- Comparatively-inexpensive materials

- Excellent heat resistance

Applications

Nozzle, Semiconductor manufacturing equipment parts, High temperature insulating parts

Zirconia

Zirconia provides the highest strength and toughness at RT.

Feature

- Excellent fracture toughness

- Excellent chemical durability

- Excellent wear resistance and self-lubrication

- Available high precision finishing

- Prevents light reflection with black color Zirconia

Applications

Oilless bearing, Electronic components inspection equipment parts, Mold parts, Guide roller, Wear-resistantparts and fixtures

● Black color Zirconia is also available. Its demand is growing in the field of image processing inspection device for anti-reflection parts .

Silicon-carbide

Silicon-carbide provides an excellent rigidity and corrosion resistance.

Feature

- Excellent corrosion resistance

- Maintains its flexural strength at high temperature.

- High thermal conductivity

Applications

Semiconductor and LCD panel manufacturing equipment parts, Heat resisting parts, Anti corrosive parts,Shelf board treatment parts